The tomatoes were great and I had more than we could consume on a daily base so I froze plenty after making tomato sauce from them. The zucchini are still growing too, but not as fast as they did during July and August. Perhaps I give up on the peppers because they were late and are so plentiful, huge, plump and inexpensive in the stores that it seems almost a waste of my effort for me to grow them. Besides I never had much luck with red ones.

Many of my flowers are done blooming for the season but there is still some colour in my flower beds and with the hot weather we are having at the moment, maybe we get to enjoy them a bit longer.

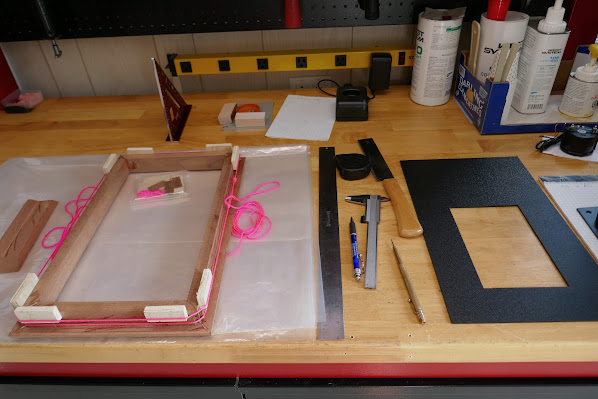

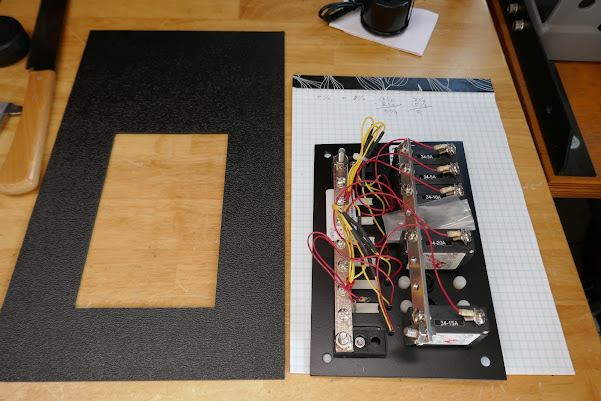

Benno had been happy that we had some cooler temps that made working in the boat so much easier. He did a lot of electrical work with hookups and rewiring. We took off the fabric ceiling material as many of the wires are now running there. They will be hidden under a false ceiling and Benno finished the strapping already. Maybe you noticed, but the two vertical supports between the front windows are a bit bigger now. Inside are six wire cables in the right one and 4 (so far) in the left running down to the breakers underneath the steering console. Just like I mentioned, cables will be hidden.

Our last trip to the Toronto area netted Benno some round 3 inch long 1-3/4 stainless steel round bar pieces from the Metal Supermarket. Last week he manufactured on his lathe five covers from this 316 grade stainless steel, which are installed over now obsolete thru hull holes on the starboard site of the hull. The idea was to close those holes without major wood/paint work and this way thru hulls can be reinstalled if the need arises.

I did some more painting with the brown/beige Epoxy paint on the shelves behind the helm man’s seat. Benno is building a cabinet on top of it that required him to remove a small support using a chisel and flex grinder. Not an easy job!

Btw, in my last post I mentioned my technique of varnishing. It was taught to me by a Danish Shipwright when our sailboat “Najade” was being built and the wood used was white Oak. The way he showed me was that when using Oak (not all wood types need this) The first coat of varnish is being thinned down 50% with Mineral Spirit. It brings out the grain that can be scraped off with the metal scraper when the paint is dry. Then the next coat can be sanded lightly and if needed scraped again to take off any dust particles. After the final coat is dry the varnish is rubbed down with extra fine (0000 steel wool and 3-in-one oil) to give it a satin finish. To note, never insert your painting brush/foam/roller into the paint can as it will jell up over time. I use a coffee scoop and a plastic container from which I paint. The same goes for any other paint if you want it to last longer.

Aside from the ongoings in the boat, Benno decided he will relocate the VHF antenna from the deck to the little stub mast and therefore the present cable will be too short for that. However it is long enough to hook up the antenna if mounted to the roof of his shop to the VHF radio mounted inside his shop. He has a 12V power supply there anyway. Now if working in there he can listen to the VHF traffic on Lake Erie ;-)

I think I stop for now for this post or it will be overload. See you next time on this blog. Thanks for stopping by.