It is -1C/30F outside with a bit of blowing sleet. Benno is tough and keeps working away on the boat. But he has to walk back and forth between the boat and garage where he does his cutting. Inside the trawler the Webasto diesel heater keeps the main cabin at a decent temperature and in the forward cabin an electrical heater helps to maintain a workable condition. Also an electrical heater in our insulated garage makes it possible for Benno to do some wood cutting without freezing his b! off, but the dust is awful as it settles everywhere inside especially if he uses the router and he often has his equipment set up outside. I think soon we will have to pack it in until next spring.

|

| There is sleet blowing around and it's freezing cold! |

This past month we again did a lot of traveling. The material we use for paneling was almost used up, so we once more travelled to the Bontrager’s Surplus store in Michigan. It’s a long way from home and it felt even longer with construction and lane closures along the way. I hope we bought enough material so we don’t need a repeat. Also trips to get the lumber for Benno to mill down and then to cut into strips for the trim took some time out of being productive back home. Yes, there is a lot of time spent to source and order stuff or driving to get the materials needed. It is even a pain to get the right stainless steel screws not every hardware store carries. However, progress was made.

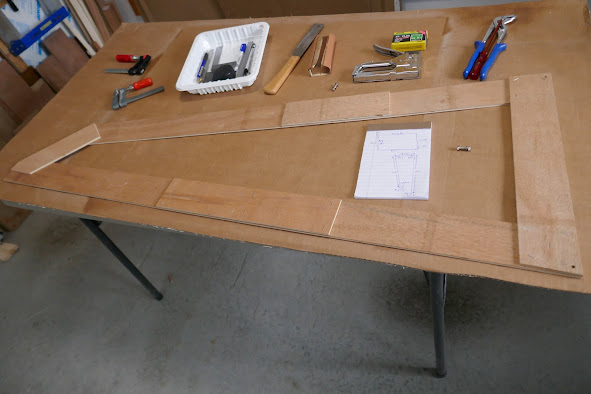

To put the work involved into prospective, I took some photos to show you the work sequence. In a boat, especially a small one, there are no straight walls to work with. Most areas are angled or curved and because we are redoing, we have to work with what was originally designed without ripping everything apart. So Benno has to make templates to make sure the panels will fit the space before actually cutting the material to avoid cutting mistakes.

|

| The making of a template, look at the notes and its size |

|

| More templates leaning at the wall |

|

| Marking the panel to be cut |

|

| Cutting of the panel |

|

| Spraying adhesive onto the cut panel |

To stiffen the panels if they are not installed onto a flat wall, Benno cuts a plywood panel the same size as the top sheet and then uses a spray adhesive to glue them together.

|

| The panel is now installed on the right side |

At the moment we are working on the head compartment (bathroom) which is very tricky in this small space. Probably the most difficult area of the whole boat. It won’t be finished this fall but hopefully close to being done.

|

| The V-berth and some wood trim ready to be installed |

The V-berth in the forward cabin we also modified. We added a removable piece at the front to fill in the gap between the two berths to make it a large V. At the foot end the two long berth boards were cut horizontal to give access to the battery below and to reach the storage area next to it. Of course those all had to have extra supports made to carry the boards. I painted everything in a beige/brown paint although the bottom will be covered with the mattress and more panels will cover the walls and some of the painted areas.

|

| The new VHF Radio installed and hooked up |

One of our trips was again to the mail depot in Detroit to pick up two orders. We got a 22 inch steering wheel and a new VHF Radio. The steering wheel presented us with a slight problem, because the steering pump shaft is a tapered shaft and did not fit our new wheel which had a straight bore. Benno dismantled the hydraulic steering pump and modified the pump shaft that it now does work with this new wheel. Thanks to his talent and his shop equipment (Lathe), I might add!

|

| The new steering wheel in working condition |

On a side note, Benno decided to purchase a hearing aid. He has worked decades servicing printing and bookbinding equipment, specifically cutting machines. Those machines were located close to very loud printing and folding machines that for sure damaged his hearing over time, on top of this when he did his 36 month military service it was with the artillery and they were shooting 155 mm shells (M44 and M109 howitzer), quite a bang!! With new technology and sophisticated hearing aids being offered, he will receive this new device next month. Because of the required tests and appointments involved, we had to make several trips to London, Ontario, to get this arranged, but we are both looking forward to this new gadget!

It will be a while yet before we are heading out with our travel trailer and I am hoping for a break in the weather when we are finally ready to go. I will let you know before we leave though.

Thanks for dropping in again.